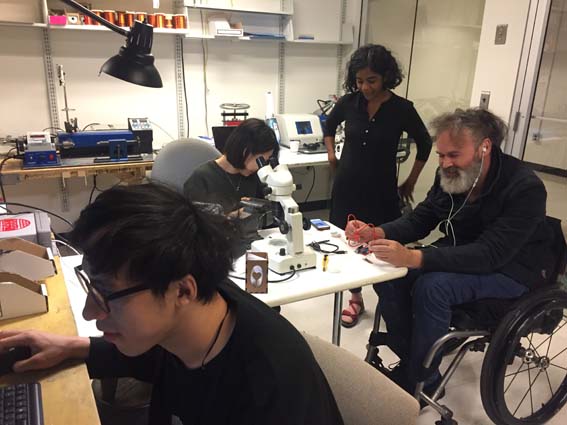

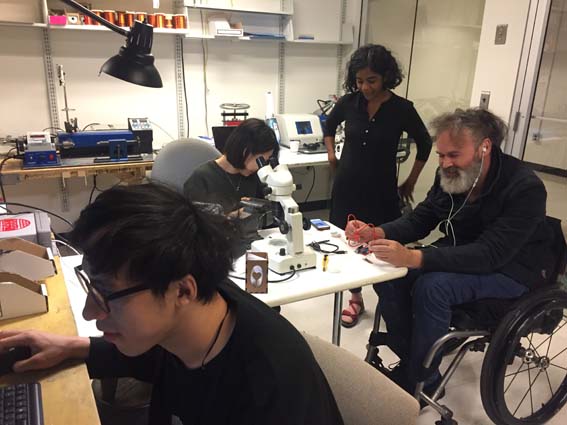

Difficult week, but it was easier with friends!

Difficult week, but it was easier with friends!

This week we tried electronics design, as a group we decided to use Eagle as Autodesk has a better platform.

The first part was kind of tricky because of the selection of the parts in the library, if you are not familiar with the terms and nomenclature of it, you can spend hours trying to pick the correct piece. Fortunately, Graham guided us through the process, as a group we picked the pieces and arranged them in Eagle.

Working with schematic can be tricky but the png. we had as a guide helped a lot, at the end it is like solving a puzzle or unraveling a very complicate thread.

Switching to Board is quite simple but disentangling of the rats nest is quite a challenge, you can play with the orientations of the components and little by little the pieces start having more sense, this also felt like making a zudoku puzzle.

It is important to load the design parameters in order to mill the board properly.

Generating a PNG once you have the traces is easy but it took a while to figure out, you just have to turn every layer off and select the ones you actually want to mill. It felt familiar to Autocad.

Milling process took a while because for some reason the translation between the image and the MOD made the image double its size, you can solve it by doubling the dpi size directly on the workflow.

After a while figuring this out I was successful but right in the milling of the outline the piece got unstuck and It almost ruined everything, I was able to stop it at the right time fortunately.

Soldering was way more easy this time.

I was able to program the board using the CBA equipment and I found it way better than in my computer. I ran the command with the help of Joao, which I recommend to visit his webpage for more detailed instructions, and was able to program the board.

Difficult week, but it was easier with friends!

Difficult week, but it was easier with friends!